Collaborative Battery Innovation from Concept to Commercialization

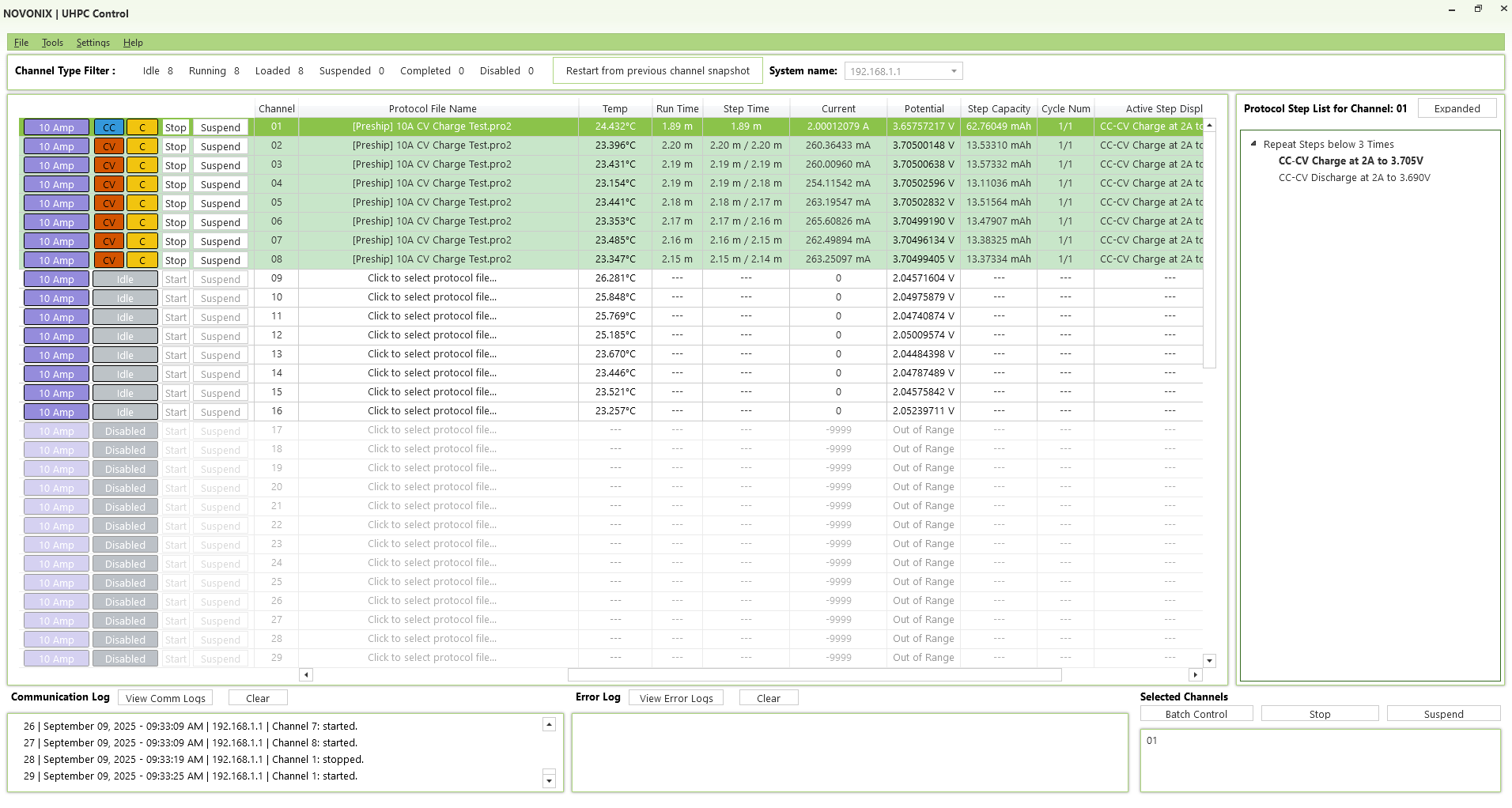

Accelerate your battery innovation with our industry-leading expertise in battery technology, material evaluation, and performance optimization. The NOVONIX team provides battery process development, custom cell prototyping and performance testing, as well as post-mortem and material analysis to help you develop longer-lasting, high-performance batteries. Our cutting-edge Ultra-High Precision Coulometry (UHPC) testing equipment provides high-value early insights to every project, complementing data from standard test methods and equipment.

Whether you are working on synthesising new anode, cathode, or conductive additive materials, novel separators or other novel battery materials, or building reference cells for electrolyte development, we have a solution for your project. Our diverse team has deep experience in a vast array of battery technologies, metrology, and engineering, including all flavors of lithium-ion, sodium-ion, lithium-metal/anode-free, and more.

- Materials development & characterization

- Cell design & Prototyping

- Cell testing and data analysis

Cell Design & Prototyping

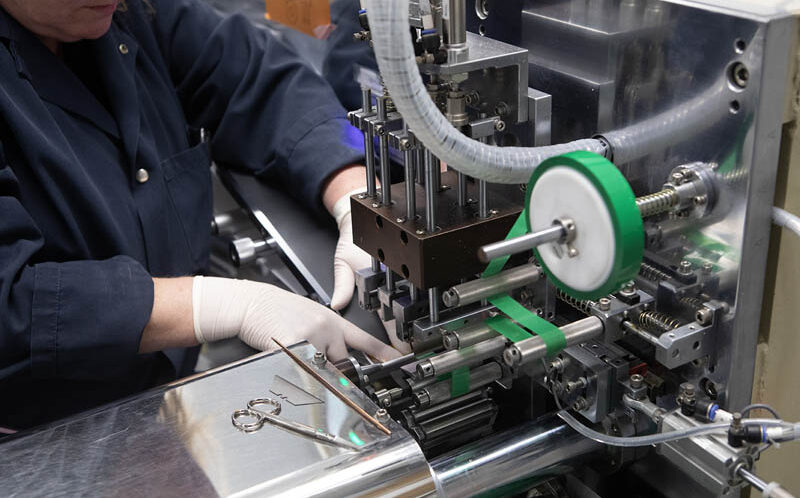

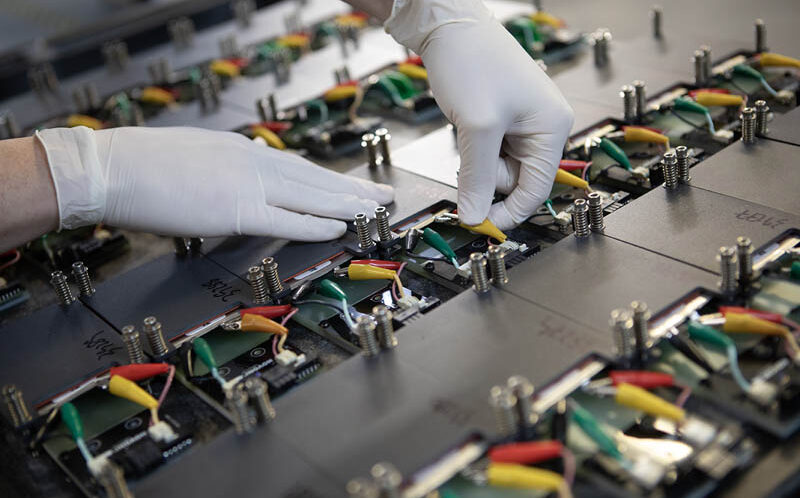

NOVONIX’s 35,000 sq. ft. pilot-scale cell manufacturing facility gives customers an edge at the R&D level. We support customers by applying deep expertise in the fields of electrochemistry and battery prototyping to validate materials, processes, and technologies—every step of the way. Our R&D services span:

Cell design and project planning

Slurry mixing from grams to kilograms

Electrode slot-die coating

Process development and parameter tuning

Cell assembly of coin cells, cylindrical cells, stacked and wound pouch cells

Cell performance and electrochemical analysis

Post-mortem and cell failure analysis

And more …

Cell Formats

Stacked Pouch

Wound Pouch

Cylindrical

Advanced Cell Testing

NOVONIX offers an extensive range of advanced testing, diagnostic tools, and electrochemical performance testing to accelerate customers’ battery research and development. Our lab is equipped with over 3,000 testing channels and thermal chambers, Electrochemical Impedance Spectroscopy (EIS), and our own UHPC testing equipment to obtain the information your team needs.

Our team of battery scientists and engineers not only design and test cells, they also analyze the data and work with your team to interpret results, make conclusions, and advance your technology. Our team of experts also provides deep insights into the results from our UHPC test equipment, helping your team make decisions and gain insight faster.

Customers We Support

- Tier 1 OEMs

- Battery end users such as electronics and automotive companies

- Active and inactive material development companies

- Academic labs

- And more

Free On-Demand Webinar

Bridging the Gap: From Concept to Market-Ready with NOVONIX R&D Services

Join Dr. Stephen Glazier, Director of Cell Technology and Ken Broom, Senior Director of Business Operations, as they explore how NOVONIX Battery Technology Solutions Services supports end-to-end cell prototyping, testing, and evaluation.

To access the webinar, please fill out the form below.

"*" indicates required fields

Latest Insights & Updates

Advancing SBR Performance in Li-Ion Batteries

Mallard Creek Polymers partnered with NOVONIX to study and compare the performance of their Styrene-Butadiene Rubber (SBR) to a commercial SBR used as an anode binder in Li-ion cell prototyping…

Application Note: Study of Solid-State Batteries

This application note highlights the value of using Ultra-High Precision Coulometry (UHPC) to test solid-state batteries – providing insights into performance, degradation mechanisms, assembly quality, and outlier behavior.

Ready to Collaborate?

Whether you’re developing next-gen battery materials or looking to validate new cell designs, NOVONIX is here to help you move faster, smarter, and with greater confidence.